TogliattiKauchuk Plant – Togliatti, Russia

Laser scanning as a method of storage of spatial information is used in various economic sectors. In this article, we will focus on laser scanning for industrial design, or more precisely on the execution of a 3D scan of the petrochemical complex for the production of synthetic rubber.

The goal was to create a three-dimensional digital model of the four plants for the production of isoprene (raw material for rubber). The TogliattiKauchuk factory is located in Togliatti, Russia and is one of the largest petrochemical enterprises producing rubber.

The project was executed by company “Acropol-Geo” with a process inspection and support of 3DLS’s specialists.

For our clients, we have successfully restored the factory-built documentation, conducted a survey of industrial facilities, performed accurate measurements for the control of construction, created topographical plans and maps, calculated volumes of mining and storage of bulk products, performed architectural measurements of buildings, scanned and simulated emergency hydraulic power units, captured the linear objects of pipeline transportation, carried out a three-dimensional modeling of complex industrial structures, and performed other activities in order to meet the objective of 3D scanning.

At the present time, many progressive development organizations use modern computer technology design in three dimensions in order to carry out these types of projects. Modern 3D-capable technology is able to rigorously account for the actual geometry of the existing facilities. They are aimed at improving the quality of the final projects, at reducing the timing of the overall scanning process and at continuous support and supervision for the entire period of the object improvement project beyond scanning.

Enterprises increasingly use 3D solutions leading vendors such as Autodesk, AVEVA, Bentley, ESRI and Intergraph for the design, engineering and project management of industrial management. The leading enterprises that use these technologies are players primarily in the oil, gas and energy industries.

Using this new technology in the object survey phase of the project, a designer receives an accurate computer copy of the real object in the form of a three-dimensional model. And dozens of workers that were previously doing this work manually are easily replaced with only one instrument, operated by one operator. Moreover, all these measurements are performed without any contact between the operator and the object, so the process of measurement does not prevent the plant from continuing to conduct its business as usual. Such measurements at the TogliattiKauchuk plant was carried out by laser scanner FARO Laser Scanner Focus-3D and Leica ScanStation C10.

The field work of the scanning of the plant was carried out by a team of four specialists in 34 working days, and consisted of two parts:

Creation of the geodetic net Laser scanning of the object’s elements.

The technology allows to perform these two processes in parallel.

Pict1. Working meeting

The work was carried out on an area of 5 hectares. However, multi-level interlocking of cables and tubes of different diameters, hundreds of technology setup areas, equipment, facilities, tanks and furnaces increased the technological complexity of the object and its scanning. Shooting conditions were close to extreme: functioning harmful production process, vibration, noise, high temperature piping, the presence of high-pressure steam, harmful chemical emissions, etc.

Pict2. Laser scanner positioning

All elements of the object were subject to scanning, including each flange. Scanning was done from a total of 8,158 positions to achieve the maximum coverage of the elements of the measurement object. The total number of single measurements (in the point cloud) exceeded 12.5 billion. In order to reduce the time, in which this field phase of work was completed, the technology approach of “total scan” was used. The use of a standard survey methods (the use of the order of 7 spheres or marks on each scan) and merge of such a large amount of data would have required 5-6 times more time. Additionally, the use of propriatary software allowed to solve successfully the problem of compensation for fluctuations and vibrations.

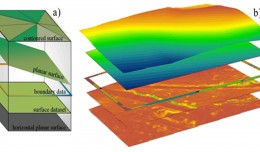

The postprocessing phase consisted of the following:

Pretreatment of scans using FARO Scene software

Alignment of the scans in InnovMetric PolyWorks software

Registration of scans in the coordinate system of the plant

Build and control of scan alignment performed in Leica Cyclone software

Creating 3D models in Bentley MicroStation software

Conversion of 3D model into PDMSmac format.

We used software Leica Cyclone 7.3.3 64-bit for final merging of aligned scans. The advantage of Leica Cyclone version 64-bit is to use all available RAM (we had RAM 128Gb). Unlike analogous software Leica Cyclone works faster and more correctly with huge point clouds: visualize, registration quality control, merge point clouds, cut clouds by parts to pass it to modelers.

It should be noted that the final cloud of points contains not only the structure of the scan but also the transformations of the scans that have taken place during the alignment process in Leica Cyclone. If necessary, this alignment can be re-registered and transformed into a different coordinate system, where new elements of related objects can be added (for example in the case of continuing reconstruction work at the factory).

The final 3D scan included every single one of the 12.5 billion real measurements that were captured during the scanning process. The customer got thin point clouds too to load it to AVEVA LFM for control. That data are in correct PTX format.

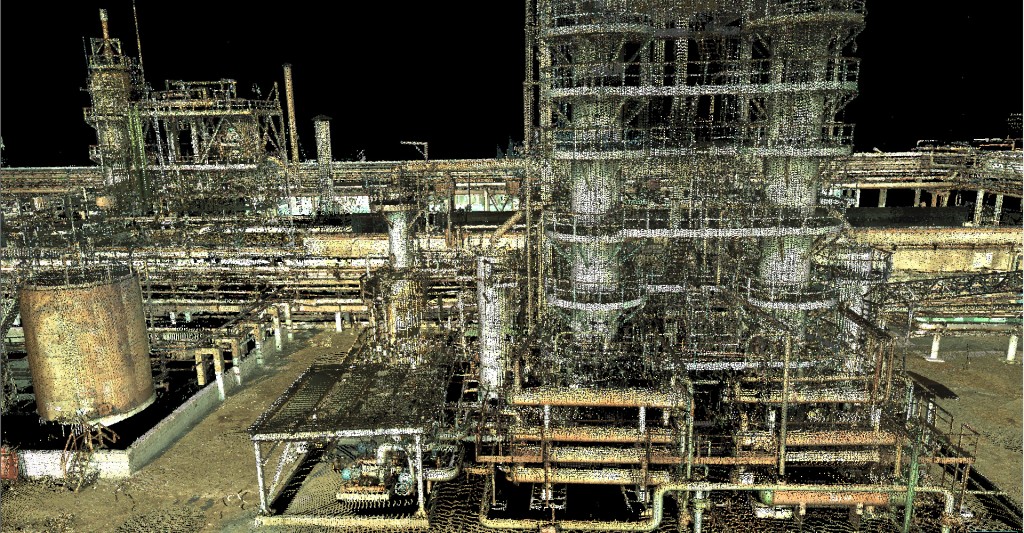

Pict3. Point clouds in Leica Cyclone

And now a few words about quality control of matching and modeling. Quality control is performed by visual analysis of cross-linked sections of the cloud of points in the software environment Leica Cyclone. Horizontal and vertical cross sections of the aligned point models have been built in order to assess the accuracy of the models. The points in these cross sections were highlighted in different colors that correspond to the various scanning stations. The quality control inspection results were positive: the maximum difference between the points of scans from different stations amounted to 12 mm compared with the desired tolerance of up to 15 mm in the assignment specification.

The high density of the cloud of points and the adequate coverage of the element measurements enabled the successful deciphering and modeling of the details of the object according to the required specifications. 3D modeling was performed by different softwares: Bentley MicroStation, Autodesk AutoCAD and Leica Cyclone. This process consisted of inserting vector geometric basics into the appropriate segmented point clouds. The final collecting and checking of 3D models was done in Bentley MicroStation.

The modeling was carried out under continuous monitoring of the results. The final step was the quality control process to determine the quality of the output results. Together, this provided for an exact match between the executed model and the real measurements of the object.

Thanks to complex and flexible tools of MicroStation it was done as a 3D modeling as collecting of 3D models from other softwares. Powerful tool of 3D visualizing and rendering created the final 3D model more demonstrable and realistic.

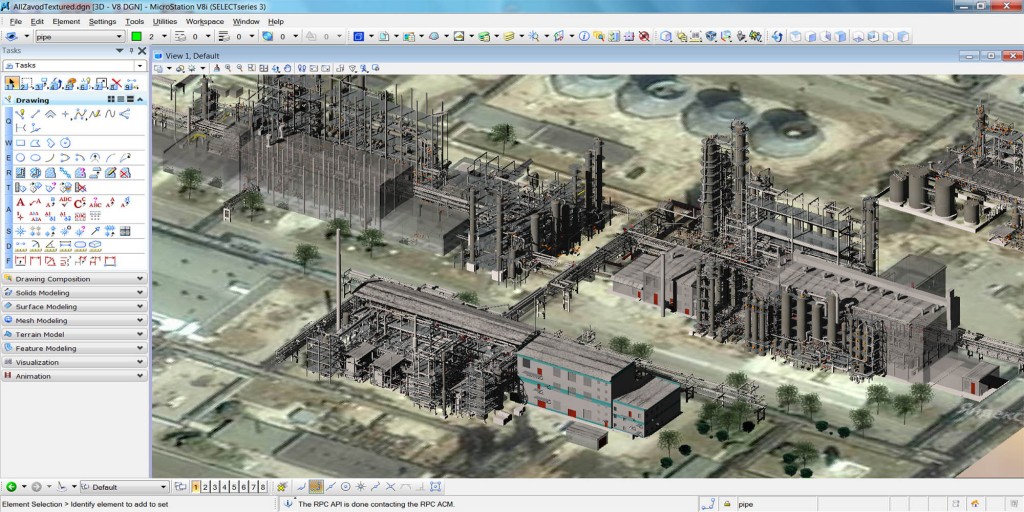

Pict4. Workshops 3D models for reengineering

Output of 3D modeling was converted to AVEVA PDMSmac format and passed to Customer for following executing of design and work documentation for reengineering of plant.

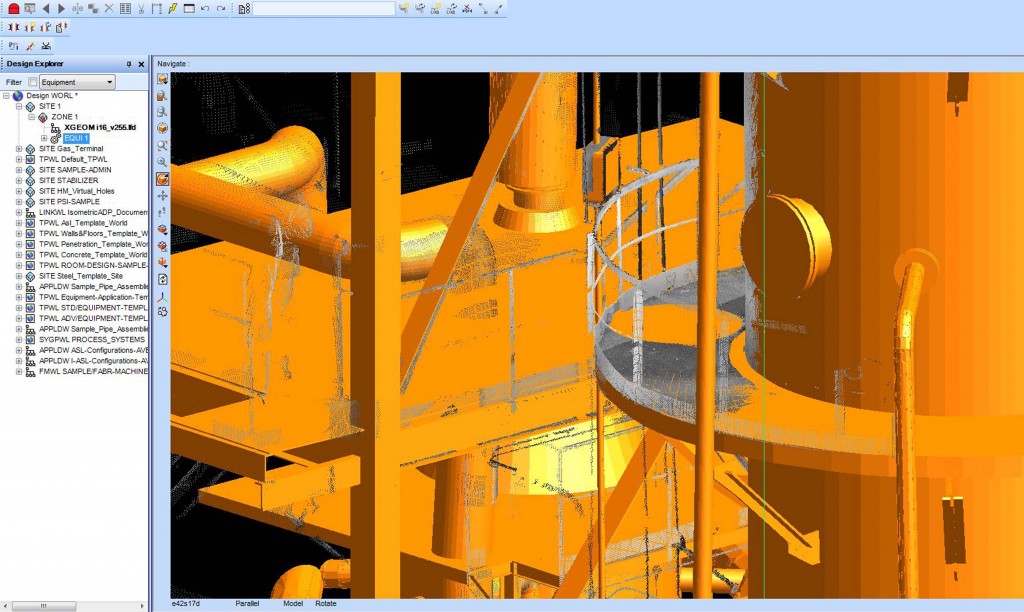

Pict5. Matching of 3D models and point clouds in AVEVA

The entire project was completed within 102 working days. As a result, the project management organization received a database in Leica Cyclone IMP-format, containing the normalized cloud of points along with credible 3D models of the plant in CAD and PDMS format within the coordinate system of the plant.

The project for the modernization of the plant will be implemented with the highest quality!

http://www.youtube.com/watch?v=6MDcIK37CJk&feature=youtu.be

info@3DLS.ru

acropolGEO@gmail.com

English

English  Français

Français  العربية

العربية